AIR COMPRESSOR

|

|

DRILL PANGOLIN & LIUTECH are teamed up to manufacture an air compressor matching KHITAN series hydraulic crawler drilling rig, reaching the drilling target of No Fastest Only Faster. LIUTECH as a multinational compressor supplier ATLAS COPCO group, a wholly owned company in China manufacturing, is a company specializing in the production of screw air compressor and its post-processing equipment manufacturer, has been committed to provide users with the compressed air system solutions. |

HOW TO DRILL BORED PILE IN THE MOUNTAIN?

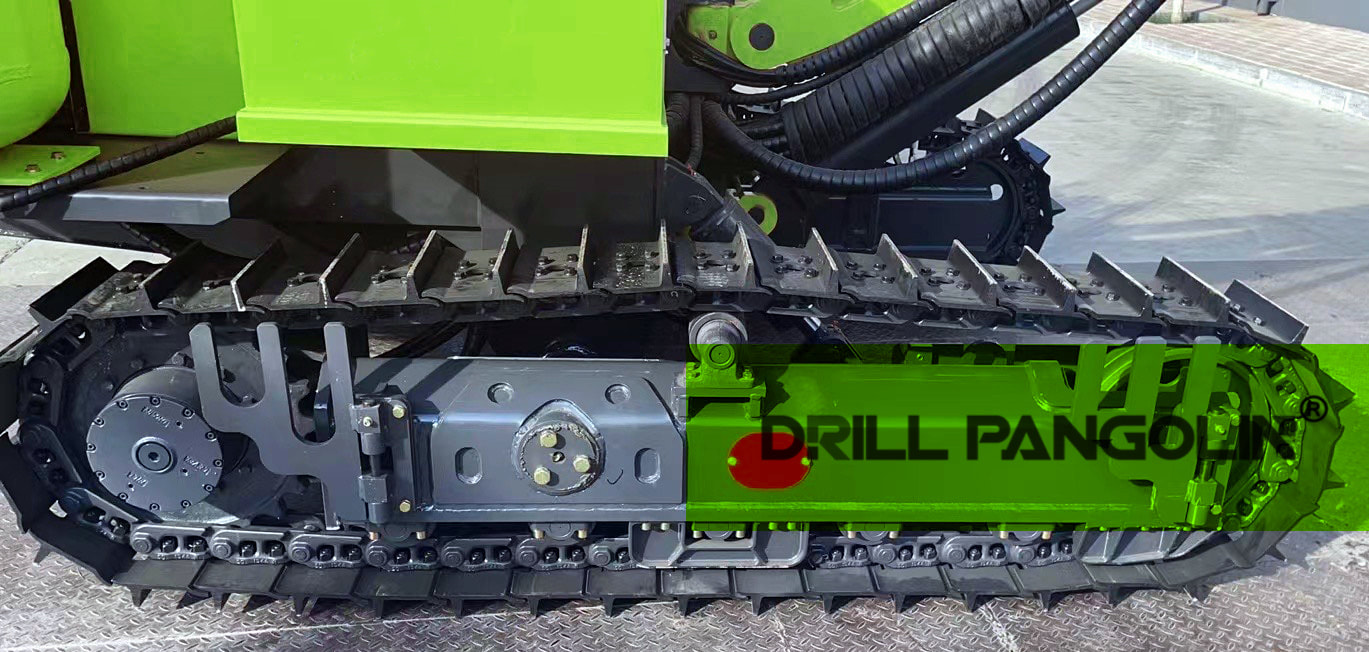

Targeting solar installation market

In the proposed plant site area, the site topography is hilly and mountainous, with structural denudation topography, eroded mid-mountain to low-medium mountain topography, and local hilltop terraces with small elevation difference. The elevation of the entire site area is between 394 and 674 meters, and the relative elevation difference is large. The slope from the middle of the mountain to the top of the mountain is between 30 and 65 degrees, and there are vertical stone cliffs in some parts. It is mainly composed of residual soil, strongly weathered granite, moderately weathered granite and slightly weathered granite.

The solar cell module of this project adopts a fixed support, the installation inclination is 36 degrees, the total installation capacity is 11.44MWp, and it is divided into 10 photovoltaic square arrays. The project plans to use micro-porous cast-in-place piles as the support foundation, with a total of 20,000 pile foundations. The pile foundation is 3 meters deep and 305 mm in diameter. It is completed by pouring C25 concrete. Due to the large slope of the mountain, the construction of the pile foundation and the transportation of materials to the mountain are the difficulties in the construction of this photovoltaic power station.

The overall construction process of microporous bored piles for large-slope mountain photovoltaic power stations is as follows:

Drilling and forming of large-slope bored piles

The solar cell module of this project adopts a fixed support, the installation inclination is 36 degrees, the total installation capacity is 11.44MWp, and it is divided into 10 photovoltaic square arrays. The project plans to use micro-porous cast-in-place piles as the support foundation, with a total of 20,000 pile foundations. The pile foundation is 3 meters deep and 305 mm in diameter. It is completed by pouring C25 concrete. Due to the large slope of the mountain, the construction of the pile foundation and the transportation of materials to the mountain are the difficulties in the construction of this photovoltaic power station.

The overall construction process of microporous bored piles for large-slope mountain photovoltaic power stations is as follows:

- Pay-off measurement basic center positioning

- Drilling

- Reinforcement cage embedded parts placement

- Concrete pouring

- Concrete curing

- center line

- Elevation

- Squareness detection

Drilling and forming of large-slope bored piles

- For drilling solar panel pilot holes on the mountain with steep slopes, we use two units DRILL PAGNOLIN® APOLLO solar drill rigs to cooperate with each other. One of APOLLO solar drill rig is parked on the road on the half-hill slope as a tractor, the other APOLLO solar drill rig is drilling holes on the hillside, and the two solar drilling rigs are fixed on the the car half-shaft guide wire rope on the top of the mountain is connected, and the two drillers of solar rigs communicate with each other through the walkie-talkie, and send a special person to monitor the safety.

- On the top of the mountain, the car half shaft guide wire rope is used. The car half shaft is buried underground with a depth of about two meters. The wire rope is guided by the half shaft to connect the two APOLLO solar drilling rigs. The semi-axle of the car buried in the top of the mountain is equivalent to the fixed pulley which plays the role of fixing and guiding the wire rope.

- The firmness test was carried out before the official drilling. The two APOLLO solar drill rig drillers cooperated with each other through the walkie-talkie. After issuing the start operation command, the tractor began to move forward slowly on the half-mountain road, while the other drilling rig began to move down the mountain to reach the designated location. After the position, the two APOLLO solar drill rig stopped at the same time, and the pulling drilling rig used the wire rope to pierce the drilling rigs to prevent sliding or rollover. The solar drilling rig on the hillside began to drill. Looseness of the half shaft. If there is no looseness, it means that the fixed point is firm and reliable. If there is looseness, stop drilling immediately and replace the fixed point until it is qualified.

- When one hole is finished, the driller who punches the hole gives an instruction to punch the next hole, and the two APOLLO solar drill rigs move at the same time, and the drilling operation is carried out through this cooperation.

- When drilling, the drill rod should be lowered slowly first, so that the drill bit is aligned with the hole position, and the drill rod must keep vertical. If the hole drilling is stuck during the drilling process, the power supply of the APOLLO solar drill rig should be cut off immediately, and the drilling should be stopped. Do not force the solar panel pilot hole drilling rig to start before the cause is identified. , When it is drilling, when the drill arm shakes, moves, deflects or makes rhythmic noises in the drill bit, the drilling should be stopped immediately, and the construction can be continued after treatment.

- During operation, when it is necessary to change the rotation direction of the drill rod, it should be carried out after the drill rod is completely stopped.

- After the operation, the drill rod and the drill bit should be lifted out of the hole, the soil on the drill rod should be removed first, and then the drill bit should be pressed down to contact the ground, the brake columns of each part, and the joystick should be placed in the neutral position to cut off the power source.

- The drill rod must be vertical during the whole process of hole forming.

- The hole drilling must meet the hole depth and diameter required by the design. Allowable deviation: The displacement deviation of the hole center is less than 10mm, the relative displacement deviation of the center of the front and rear pile holes is less than 10mm, the relative displacement deviation of the center of the hole spacing is less than 20mm, and the allowable deviation of the verticality is 0.5%.

- When the wear of the drill bit reaches 20mm in diameter, it should be replaced immediately.

- After the hole is formed, attention should be paid to the maintenance of APOLLO solar drill rig.